ABIMBOLA ABATTA spent three days at Lucky Fibres Limited, a factory that manufactures the popular lush hair extension, carpets and rugs. Before going to the factory on July 31, 2023, Abatta had an inkling of what would happen. She had read stories and seen videos detailing the experiences of casual workers in factories in Nigeria. She did not just want to chronicle the daily lives and struggles of these workers; she wanted to immerse herself in their experiences. She wanted to be in their shoe for a few days and see if it would fit.

In May, a Twitter video of two women meticulously arranging biscuits in a factory went viral. The precision with which they worked intrigued many Nigerians, including me. However, the comments section told a different story, as a lot of factory workers (former and current) shared their unpleasant experiences working in factories across the country. While many described the work as a form of modern slavery, others decried the low wages that accompany the job.

I found another video on Facebook in July, showing a man at work in a hair factory. He was combing hair extensions in large amounts, and many of the comments under the post mirrored the lamentations under the Twitter video.

Upon watching these two videos, I felt compelled to spend a few days working in a factory to document the experiences of factory workers. My time at the factory was beyond an undercover mission; it was a journey into the heart of humanity’s resilience and the sacrifices made to earn a living.

LUCKY FIBRES

With just N300 and a pseudonym, I gained entry into Lucky Fibres as a casual worker. You don’t need certifications, a curriculum vitae or even an interview to be employed as a casual worker in a factory like this. I had earlier seen an advertisement online, calling for interested factory workers. I contacted Sala (not real name), the recruiter, and got in. But not without paying N300 to obtain an identity card, which granted me access to the factory for the rest of my stay there.

Sala had disclosed in his advertisement that workers’ monthly income was N35,000 and above. He also stated that the job came with accommodation at N2,500 per month.

Lucky Fibres sits in Ikorodu, Lagos State, and is just a few minutes’ drive from the Lagos State University of Science and Technology (LASUSTECH). The big signpost at the entrance of the factory was unmistakable as I alighted from the tricycle that brought me there that morning.

As I got there at exactly 7:09 am on Monday, the teeming crowd caught my attention. I would later learn that many of them were new faces like mine, awaiting our respective recruiters or contractors to usher us into the world of factory work.

While I waited for Sala, I could see workers in ones and multiples coming out of the small gate. The big gates were only opened to allow vehicles in. Those who were coming out were workers who had worked night shifts and were heading home.

When it was time to enter the gated company around 7:44 am, I stood in a queue with the other newbies, while a well-built, dark-complexioned man called out our names from a stack of papers. As earlier instructed by our recruiters, each of us had written down our names on pieces of paper they provided.

Those of us whose names were called entered through a small gate with unsure, nervous steps, like students on their first day at a new school. The prospect of being a factory worker for the first time in my life made me giddy with excitement. But the fear of the unknown lurked in the shadows of my heart.

Some new recruits and I had to wait close to the security post while others walked ahead of us. But I did not have to wait for too long, as my recruiter led me and two others into the factory.

As I walked on the tarred road into what I would later describe as undeserving suffering, my gaze wandered around the expanse of land that housed the company called Lucky Fibres.

We moved past a few security guards, various buildings and trucks with ‘Lush Hair’ inscriptions.

We were soon at another entrance, manned by security guards (a man and a woman) who rummaged through our bags, pockets and clothes before allowing us in. This entrance only allowed workers inside the factory. There is an exit at the other end of the building, where security guards would equally do a quick search before letting you out.

From there, I found myself inside a spacious hall that seemed like a beehive. On one side, operators rolled down fibres into various hair extension products for workers on the ground floor. Young men brushed large volumes of hair extensions on big hair hackles with surreal vigour. Table workers were scaling, tying and brushing on smaller hackles and packing the hair while sealers were sealing the packets and arranging them in cartons.

My eyes ran over the sea of hands and legs flurrying by in a race of activities at Lucky Fibres. It was an orchestra of uncoordinated noise and a sight to behold.

INDUCTION

From the hall, we were ushered into a large canteen where the aroma of food wafted through the air, constantly reminding me of the hunger pangs that gnawed my stomach.

Right there at the canteen, we were inducted into the company’s work culture. I strained my ears to hear the speakers over the buzzing noise from the canteen. Workers trooped in and out, chattering away like birds.

The first session of the induction featured the company’s 17 rules and regulations. Some of the rules that piqued my interest were the ones banning workers from pressing phones or using earphones and earbuds while working. Also, one had to take permission from the team lead before receiving phone calls.

For the second session, bordering on health, safety, and environment (HSE), the facilitator sensitised us to workplace hazards and safety measures. At the end of the remaining sessions, someone called out our names for the second time.

But this time around, we stepped outside while the recruiters confirmed to the person calling out the names that they were ‘responsible’ for us.

Following the induction, around 11:00 am, Sala led me back to the spacious hall and then asked me to wait for him. He returned after some minutes and he took me to a table to join a group of young workers. I had earlier observed that there were only a few old workers among several young people.

During the induction, one of the speakers said the age range for workers was between 18 and 50 years. Many of the faces I saw at the factory belonged to young men and women, probably in their late teens and early or late twenties, tirelessly working at their various duty posts.

When Sala took me to where I would work for the day, I was eager to endear myself to my new colleagues. I quickly joined them in pre-packing activities, but my excitement was short-lived as a supervisor told Sala that they had enough workers for the table.

He said there was no room for me because, according to him, I came late. Even when Sala and I explained to him that I was a new worker and that I was coming directly from the induction, he insisted that there was no work for me on the table.

This made me realise that lateness was not condoned in the factory. Sala’s attempts to see if I could join another group of workers proved abortive.

He gave me my ID card after collecting N300 from me, telling me to laminate it. He said it was my access card to the factory. He also gave me a gate pass (a note), which I handed over at the main gate before taking my leave.

READ ALSO: REPORTER’S DIARY: At Lagos Market Known for Cheap Food Items, I Got 10 Tomatoes for N1000

I resumed work on Tuesday around 7:00 am. As the day progressed, an announcement rang out, that workers might not work on Wednesday due to the nationwide strike embarked upon by the National Labour Congress (NLC).

While a part of me anticipated the break, I knew the opportunity to connect with the workers might slip away. If I were to understand their reality, I had to return. This meant standing for endless hours again, but I was ready to embrace the discomfort for a chance to bear witness to their lives. Their stories needed to be heard, and I wanted to be the one to tell them.

The announcer said our contractors or team leads would reach out to us if we would work on Wednesday. I had dressed up for the day, but I had still not heard from Sala. So, I contacted him, and he said we would resume on Thursday due to the strike. For casual workers, no work, no pay.

CONTRACTORS

Lucky Fibres’ Lush Hair factory works with different contractors. Each contractor has recruiters who bring in new workers. Sala, the guy who recruited me, works for a contractor whose venture’s name was visible on my ID card. So, rather than showing that I work directly under Lucky Fibres, the ID card shows that I am the contractor’s staff member at Lucky Fibre.

So, it is normal to find workers with ID cards bearing different names of contractors working for Lucky Fibre. But how do they make their money? When I asked Faridah, a colleague at the factory, she explained that contractors get paid based on the products delivered by their staff members.

“They make money on our (their staff) work although they don’t deduct from our money,” said Faridah.

“Does the management pay them commissions based on what workers deliver?” I asked.

“Yes, but they won’t deduct our money. Even if they do, it could be around N300 or thereabouts. And if you complain… For instance, you could do a job worth N12,000 and they may pay you N5000. If you don’t complain, that’s the end. So, as a worker, you must write down what you earn for each day you work.”

She also said our own contractor was nicer than others because one could buy food on credit and pay on payday.

“If you are hungry, you can buy on credit, and the contractors will just deduct the money from your salary. Our boss is good because he won’t take an interest. Many other contractors will demand interest when you buy food on credit,” said Faridah.

PROLONGED STANDING HOURS

One thing that stood out at Lucky Fibres was how many of the workers worked in a standing position. I later found out that standing for prolonged hours while working at this factory was the norm.

I could count on two hands the number of workers who sat on stacks of plastic stools. I also learned that you could steal a few minutes to sit if your team leader was far away. But that can only happen if you are lucky enough to secure a stool before others, as there are limited chairs there.

I was also cautioned against sitting because I could either receive a barrage of insults or be sent home if an overzealous team lead or supervisor felt I was slowing down the work by sitting down. I had no choice but to stand for long hours while I worked there. I had never had any reason to stand for hours the way I stood while working at Lucky Fibres.

“You’ll soon get used to it so much that you won’t even like to sit down anymore,” Simbiat, one of the table workers, told me.

I remember seeing a team leader shout at a worker in a fit of rage all because she sat for some minutes. She insinuated that the lady was lazy, but even while the young lady briefly sat down, she was occupied with work.

“You! Get up! Why you dey sit down? You no see work on ground? If you no wan work, dey go your house!” Said the supervisor.

I felt so bad for the lady because I could feel her pain at that moment. She had to reluctantly stand up and continue working. I knew she wouldn’t have gone home because that meant her entire work for the day was a waste — she wouldn’t get a dime.

“That woman screaming has sent a lot of people away with her attitude. She screams at people all the time, insulting them unnecessarily,” Simbiat told me.

“Many people left on their first day here because of this. You can never receive a commendation from her. All she does is find fault with people.”

WORK SHIFTS, EPILEPTIC WORK HOURS

Also, just as the workers’ income was unstable, closing hours were also not fixed. If you were on the morning shift, you could work from 7:00 am to 7:00 pm.

If you were on the night shift too, you could work from 7:00 pm until 7 am. However, the time could change slightly if your table didn’t have enough workers (especially brushes) or your teammates weren’t fast enough.

So, while working on your feet, you must have speed and accuracy skills, because the absence of these could affect your daily income.

When a senior workers moving around shouts “No leftovers! No leftovers!” It means workers at a table must finish up the day’s tasks before going home. It also means having leftovers could affect the following day’s work because one has to finish up the previous day’s work before starting a new one.

“Sometimes, you might still be working after 7 in the morning or evening, depending on your shift. In fact, we have worked till around 11:00 pm before,” said Faridah.

When I asked her about the implications of leaving after 7 while the work was yet to be completed, she said it would be considered as though one had not worked for the day.

“If you go home because it is past 7 and people are still working on your table, you will not write attendance and you will not get paid for that day,” she said.

“Whether you worked or not doesn’t matter. You just have to wait for the team to wrap up the day’s work.”

CHEAP LABOUR, LOW WAGES… DO THEY REALLY EARN N35,000 MONTHLY?

That Tuesday, I was to undergo training, which involved actively learning while joining my fellow workers in the activities for the day.

The recruiter had told me that while my work during the training period would not count towards the target work, I would get a thousand naira for each day of the three-day training. This was to be paid alongside my salary on payday.

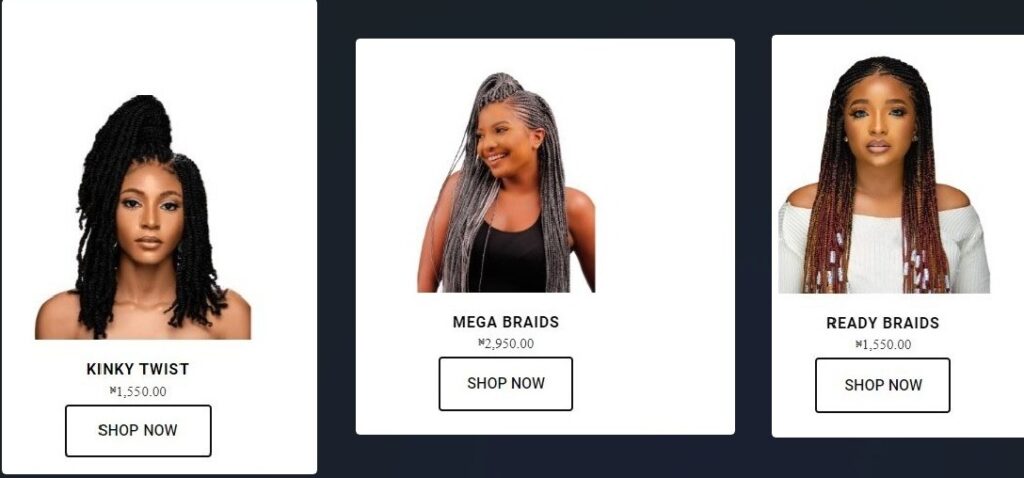

I learned to scale hair extensions, balance them, tie them neatly with rubber bands and fancy rubber and then pack them into either ready braids or mega braids.

What I just described might seem easy, but I kid you not, it was quite taxing. By the time we were done for the day, I was physically drained and mentally exhausted. If body pain were a lady, it would have been me.

My legs felt heavy, as though they were carrying a mountain of weight. My back screamed with a sharp, stabbing pain. My feet and wrists hurt so much that I had to use a pain reliever when I got home. I felt like the embodiment of pain. But my teammates were already used to it.

READ ALSO: The Poet: ‘Hunger Made My Mother Mad’

‘WE HAVE NO CHOICE’

Faridah, one of the workers, said I must have earned N1500 daily for 20 days if I wanted to make at least N30,000 on payday.

“How hard can it be to make N1500 a day, considering all the work we did for the day?” I thought. Alas, I was wrong! You could work from morning until evening and only earn less than N1,000.

Sala had earlier told me during the recruitment process that depending on how hardworking I was, I could make between N1,000 and N2,000 daily.

But Faridah told me that making N2,000 a day was not impossible, but it was difficult. She said one could earn as little as N100 in a day.

“The work is stressful, but what choice do we have?” She said.

N350 FOR A CARTON OF 30 PACKETS OF READY BRAIDS, N525 FOR MEGA BRAIDS

I was told that while workers get paid at the end of the month, their salary is not stable, as each worker’s daily earnings determine what one would earn on payday.

For instance, six of us (table workers) scaled, tied and packaged nine cartons of Ready Braids between 7:40 am and 6:00 pm on Tuesday.

Each carton contains 30 packets of hair extensions, but only N350 is paid for one carton at N11.6 per packet. This means that nine cartons of Ready Braids cost N3,150. It also means that the 11-hour job done by the six of us was only worth N3,150.

To calculate the table workers’ wages for Tuesday, they had to divide N3,150 among the six of us. But because I was still a trainee, the money was to be shared among the other five. And so for Tuesday, the wage for each worker was N630.

On another day, six of us did nine cartons of Ready Braids and five cartons of Mega Braids between 7:15 am and 6:56 pm. There are 20 packets of hair extensions in a Mega Braids carton, and one carton gives table workers only N525 at N26 per packet.

So, if nine cartons of Ready Braids equal N3,150, five cartons of Mega Braids equal N2,625. The value of the entire day’s work was N5,775 only. When shared among five workers, excluding me, each worker earned N1,155 for the day.

Altogether, two days’ income for the table workers I worked with only gave them N1,785.

I came to understand that the more workers who work at a table, the more cartons of attachments they will be able to deliver. But it also means lower wages. But then, the smaller the workers at a table, the smaller the target for the day.

Faridah even told me that each carton of hair extensions must meet certain measurements or their work would be invalidated.

“If we have a low scale, we must correct it by unpacking and untying all the attachments and then rescaling. Each strand of attachment in each packet must weigh between 97 and 100 grammes,” she said.

“If at the end of the day, the supervisors find out that the entire carton failed to meet the required measurement, we will either work on it again or they will give it to another group to work on. And if another group should work on it, we will not get paid for the day.”

In the course of our discussion on my last day there, Faridah told me that she joined the factory a month earlier because she needed money for her freedom from her apprenticeship.

“I have been learning nursing for the past six years, and now, it is time for freedom. The things I need for freedom are a lump sum of N150,000, a bag of rice and carbonated drinks,” she said.

“I don’t have the money right now. And my parents can’t even afford such an amount. So I have to work. I took some time from my boss so I could work for a few months.”

N6 TO TWIST A PACK, N13 TO UNTWIST

I would later learn from another worker in a different department that the low wages earned by workers cut across several departments.

I met Irene at Ikorodu Garage on Tuesday, and luckily, we were both going to Lucky Fibres that morning. We quickly became friends.

A different recruiter had brought her there, and she was told that she could make huge money daily. But she found the opposite. Irene was to work at the department that produces Kinky Twist.

Kinky Twist is another brand of hair extension produced by Lush Hair. Each packet contains 10 rolls of attachment. The method of producing this kind of hair extension was quite different from Ready and Mega braids.

Workers had to first twist the already measured kinky attachment before they would untwist them to form the texture needed for Kinky Twist.

Two days after Irene joined the company, her palms were like rumpled paper. They were also red from the several twists she had to do each day. Unlike my unit, where workers work as a team, dividing the amount made for the day among themselves, Irene had the choice of setting a target for herself.

“Twisting a packet of Kinky Twists will give me only N6. And if I untwist it, I will get N13 on one packet,” she told me one afternoon while we ate at the canteen.

If Irene wishes to make N1,000 in a day, she has to either twist 167 packets of Kinky Hair or untwist 77 packets of the hair. 167 packets mean twisting 1,670 Kinky Hair in a day, while the latter means untwisting 770 mini strands of Kinky hair daily.

“But it is not even easy. I am still learning how to twist. They are teaching us how to twist. And if I don’t twist it well, it won’t count towards my earnings. It is really stressful,” she said.

“I am only doing this because I need money to pay my son’s school fees. They will soon resume. And I still have four younger siblings to look after. My aged mother is there too.

“And I am tired already, to be honest. I am a tailor, but it’s not even bringing in enough money.”

As we were talking, Irene told me that she shared the last N1,000 with her younger siblings as well as with her son. I could hear the tremor in her voice when she said she had to trek a long distance before boarding a vehicle to the factory that morning.

At the time we were talking, she only had N100 left with her, and she was prepared to cover enough distance on foot before using the money to board a vehicle home.

FACTORY WORKERS GET LOW WAGES FOR PRODUCTS SOLD IN THOUSANDS

I checked Lush Hair’s website for the cost of Ready Braids, Mega Braids and Kinky Twist, and the prices made me numb with shock. One packet of Ready Braids costs N1,550, Mega Braids cost N2,950 while Kinky Twist costs N1,550 per packet.

I also visited Ketu market in Lagos to do a market survey of these three types of hair extensions, and even though they slightly differed from the prices seen on Lush Hair’s website, they were also in thousands.

A wholesale shop in Ketu sells a packet of Kinky Twist for N1,350, Mega Braids for N2,650 and Ready Braids for N1,350. A retail shop I visited sold a packet of Mega Braids for N3,200, Kinky Twist for N1700 (another shop sells for N1600) and Ready Braids for N1,600.

The stark differences between what these casual workers earn and the price tag for these various brands of hair extensions are like comparing the vast expanse of the ocean to a drop of water.

Since a carton of Ready Braids contains 30 packets, a carton sold at N1,550 each will give the factory N46,500. But table workers like Faridah, Simbiat and me will only earn N350 at N11.6 per packet on one carton.

So, on one hand, you have individuals toiling tirelessly for meagre wages, barely able to make ends meet. On the other hand, you have these Lush hair products commanding exorbitant prices.

This highlights the disparity between the economic realities faced by the casual labour force and the opulence associated with certain products and brands.

I can never forget the derisive laugh from Faridah when I asked if Lucky Fibres workers would be able to save part of their salary.

“Save what? From which money? You are so funny o. We are living from hand to mouth. Sometimes, your salary will not even cover the debt you would have incurred before payday. There is no room for savings o except you don’t have parents, siblings, children, or other responsibilities,” she said.

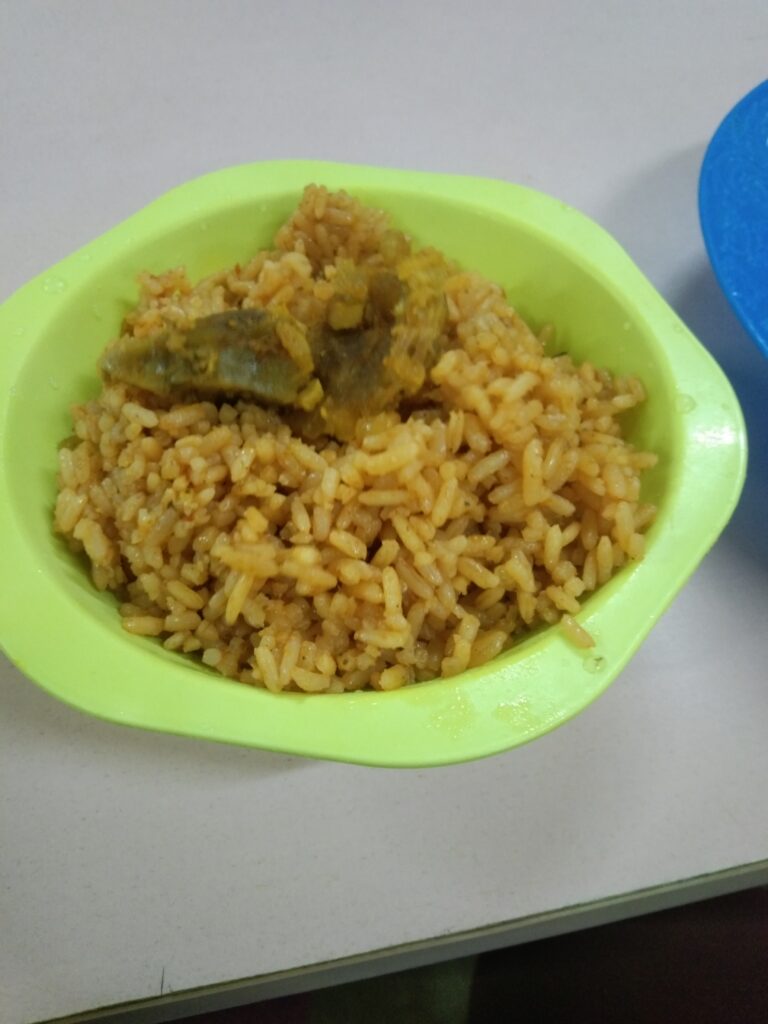

I also remember the day I bought a N300 vegetable salad alongside the N300 rice I had bought, and she literally called me a rich woman. This further made me understand that many of those who work here see common foods as a luxury.

This was confirmed by another worker, a guy who described with pride how he spent “a whole N1,000 on food the moment he received his July salary.”

LABOUR LAWS

Not once or twice did I hear the phrase ‘labour laws’ from different workers on my table. It was mostly mentioned when a team lead was lamenting the slow work rate or when workers were quarrelling.

Curious to know what it meant, I asked Faridah, and she told me it was just a kind of slang spoken among workers.

“A quality control (QC) officer could apply labour laws on you by frustrating your efforts,” she disclosed.

“You will always find QCs moving about to check people’s work. If you are rude or disrespectful to them, they can say your work was not properly done, even if it’s not true. And if they say that, it means two things: you either start the work all over again or you won’t earn a dime for the day.”

She told me that a QC once belittled some table workers’ efforts “because one of them was disrespectful.”

“The worker had to apologise and even buy a bottle of drink to appease the official. That was when the table was left alone.”

A team lead or a supervisor could also apply labour laws to seemingly lazy or disrespectful workers.

While I was there, whenever I heard ‘labour laws’, I knew it was a warning message to fellow workers to avoid getting punished.

SOME SLEEP AT THE CANTEEN, SOME AT THE LODGE

When I told Faridah that I spent more than a thousand naira daily on fares, she said, “You will spend all your salary on transportation if you don’t stay at the lodge.”

She told me that the contractors had different lodges where workers were housed for a fee. The accommodation fee comprises N1,500 for rent and N1000 for electricity, and it is often deducted from workers’ salaries on each payday.

But the lodges are either congested or not conducive. In fact, during the induction, we were informed that those who desired to stay at the lodges should not expect luxury or comfort. “It’s just a place for you to rest your head and resume work,” one of the officials told us.

There are about 15 workers at Faridah’s lodge. When I paid her a visit after the day’s work, true to the caveat during the induction, it was not a mansion.

Though they had electricity, they had to walk two or three houses away to fetch water. And for me, it was too far a distance to cover on foot to and from work every day. But the distance did not faze Faridah, who kept telling me “It’s not that far” and “You will definitely get used to it.”

She even told me that another lodge belonging to a different contractor had 40 workers living in a room and a parlour. So, for her, her lodge was much better than that.

Also, according to Faridah, workers who cannot afford to spend N2,500 monthly on accommodation often sleep on the chairs at the canteen through Monday and Friday. And since Saturday work is not compulsory, these workers would go to their respective families and homes at the weekend and then resume on Monday.

“But the issue with sleeping at the canteen is that it is always noisy, and those who want to eat could wake them and force them to vacate those seats at any time. They cannot complain. They will also have to take their bath in the restroom as early as possible,” she said.

JOB SECURITY AND PERKS

“The management rarely sacks workers because they are different sections here where even new hundred workers could work every day. So, as people are going, new people are coming,” Faridah told me one afternoon.

She also said the management could elevate hard-working workers who were loyal and committed to the company. For instance, some of the QCs were those who had worked for at least one or two years as table workers, she said.

But then, working there for a long time does not in any way impact your income except you are elevated. This means that two years after joining the company, one could still be earning meagre income.

Salat, another worker at the factory, told me that the company often rewarded loyalty, as casual workers with relevant qualifications could be employed in administrative roles as permanent workers.

“As long as you are a graduate of a university, polytechnic or college of education, whenever the management needs to employ permanent staff, they often announce that casual workers could apply,” she said.

During the induction of new workers, we were told that we were eligible for food coupons once a day after spending a month there. The coupon could be N175 or N200.

As I headed home on Thursday evening, I wondered if the workers were really as lucky as the name ‘Lucky Fibres’ implies. I could not help but connect the fact that the deplorable road network leading to the factory foreshadowed my rocky experiences at Lucky Fibres.

For a hair manufacturing factory worker to make the minimum wage in a month, they must earn N1500 daily. But the efforts invested in earning that pittance are not commensurate with what they get.

You cannot place your head on the table, and you must not be caught pressing your phone while working. Once it is seized, you will only get it at the closing hour.

I saw the imprints of fear and resignation on the faces of two elderly women working at my table as the team lead, who was young enough to be a daughter to them, addressed them in a condescending tone.

These were women who did not mind standing all day. They were nothing short of diligent while I worked with them. Meanwhile, the team leads, supervisors and contractors do not have to work because their income is certain as long as the operators, brushers, table workers and sealers do their jobs well.

“Mama, don’t you want to go home? I want to go home! Be fast with what you are doing. You people are too lazy! Since morning, what have you done?” A team lead questioned one of the elderly women.

As she screamed her head off, the two women could only murmur for fear of being punished with ‘labour laws’ should they be deemed disrespectful.

Note: Names were changed to protect the identities of sources.

This story was produced with support from the Wole Soyinka Centre for Investigative Journalism (WSCIJ) under the Collaborative Media Engagement for Development Inclusivity and Accountability project (CMEDIA) funded by the MacArthur Foundation